-

-

Shot blasting of casts, forged and pressed, parts, remodelled cold or hot and of various and complicated forms, springs, etc. (weighing up to 1,000 kg and manufactured in smaller and large series, the volume of a particular filling may be up to 2,000 L, mass up to 5,000 Kg), Cleaning surface, removing casting sand and filings and consolidating the surface (microhandling), roughing the surface before the colouring, etc.

Machines have a perpetual caterpillar made from steel flaps. Treated objects are put by a special filling contraction to caterpillar. When caterpillar moves its special shape causes treated objects to turn and roll, which causes the whole surface of the treated objects to be quality blasted in a jet of abrasive. For emptying, caterpillar is started-up in the opposite direction turning mode.

Videos

Basic specification

| MACHINE TYPE | G-150 | G-250-1 | G-450-1 | G-750-2 | G-1100-2 | G-2000-2 |

| Charging volume (l) | 150 | 250 | 500 | 750 | 1100 | 2000 |

| Max. recommended charging weight (kg) | 300 | 500 | 1000 | 1500 | 2500 | 5000 |

| Max. recommended piece weight (kg) | 15 | 100 | 200 | 250 | 400 | 1000 |

| Width of shotblasting chamber (mm) | 850 | 1100 | 1100 | 1200 | 1700 | 2400 |

| Diameter of shotblasting chamber (mm) | 750 | 910 | 1200 | 1600 | 1450 | 1650 |

| Total installed power (kW) | 18.3 | 22.5 | 24 | 38 | 55 | 120 |

| Diameter of throwing wheel (mm) | 380 | 380 | 380 | 380 | 380 | 506 |

| Power of abrasive throwing wheels (kW) | 15 | 15 | 18.5 | 2 x 18,5 | 2 x 22 | 2 x 45 |

| Air requirements (m3 / h) | 2000 | 4500 | 5500 | 9600 | 12000 | 18000 |

| Capacity of the machine (kg / h)* | 600 | 1000 | 2000 | 3000 | 4400 | 8000 |

★Larger sizes are available, as are a huge range of options. Represented here are the Standard /Stock pre-engineered machines. Please contact us for further information.

Blasting Effect Comparison

The machine’s housing is protected by wear-resistant manganese steel. High efficiency of the machine is provided by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger machines includes: PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. The machine may be equipped with magnetic separator, vibration conveyor and variable frequency drive for the turbines.

Blast cabinet

★Welded by steel plates and profile steel, have enough strength and rigidity.★ZGMn13 steel guard plate, which is hard enough to deal with the shot blasting from 35HRC to more than 55HRC.

★High impact toughness can make full use of the reflection kinetic energy of shot to continue to blast cleaning the surface of work piece, so greatly enhance the cleaning efficiency and quality.

★High chrome wear resistant cast iron grate guard plate which protect the screw conveyor and prevent big clump to get into the hopper damaging the bottom screw conveyor

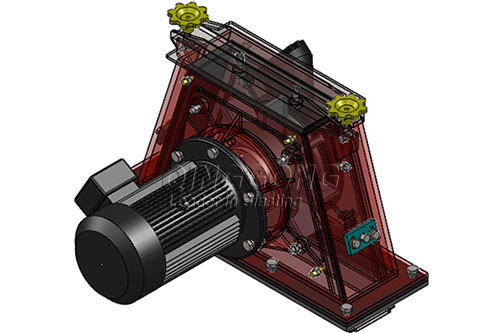

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.★impeller adopted #40 Chrome wear resistant cast iron.

★High chrome wear resistant cast iron for blades, control cage, abrasive distributor.

★Dynamic and static balance.

★Blades of impeller weight tolerance≤±1.5g.

★Unbalanced torque tolerance≤±7.5Nmm.

★Direct drive blast wheel with special motor bearings means less spare parts, less noise, energy-efficient, large abrasive flow rate and good cleaning effect ,etc. advantages.

★Machined housing ensures proper alignment of all internal parts.

★Less part wear due to greater concentricity and more precise alignment.

★Safety interlock is fitted on the housing cover to protect the workers safety.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax★Abrasive flow is indicated at the ammeter at the electrical switch and control box.

★Adjusting the bolt on the abrasive control valve can conveniently adjust the abrasive flow rate to an required amount

★In order to be able to dismount the abrasive control unit from the silo for repair works and to avoid any abrasive outflow for each unit one manual slide is installed in front of the abrasive control unit.

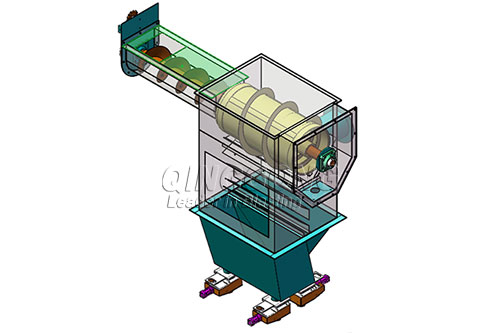

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of hte good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recyling rates of the abrasive and high quality surface finishing is achieved.

- +86-13235322903