-

-

Rotary table shot blasting machines are splitted into single rotary table shot blasting machine and swing table shot blasting machine. swing table shot blasting machine efficiency is much more higher than the single rotary table shot blasting machine.

Shot blasting parts of various shapes and dimensions, casts, forged parts, pressed parts, steel and non-ferrous metal parts and parts made from fragile materials, cleaning surface, removing casting sand and filings, consolidating the surface (microhandling), roughing the surface before colouring, etc. They are especially suitable for use in small series and individual item production because of the low price, easy installation and discontinued operating process.

Treated objects are loaded on a perforated rotating table. A big door, provide simple and fast loading. The machine can have the table fitted to the machine’s door, which enables loading with a hoist or fork-lift truck to the entire surface of the table. The machine also can equipped with two tables, enabling simultaneous shot blasting of treated objects inside the machine and loading or turning treated objects in front of the machine.

The machine’s housing is robust and protected by wear-resistant materials. High efficiency of the machine is enabled by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger machines includes: PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. For shot blasting cast containing larger quantities of casting sand a magnetic sand cleaner may be installed.

Single Rotary table blasting machine Basic Specification

| ITEM | RT1000/900 | RT1200/900 | RT2000/1500 |

| Maximum dimension of chamber (mm) | Φ1350×560 | Φ1350×860 | Φ2654×560 |

| Maximum workpiece weight (kg) | 400 | 400 | 1000 |

| Diameter of Turn Table(mm) | Φ1200 | Φ1200 | Φ2500 |

| Number of blast wheels and power (kw) | 11 | 2×7.5 | 2×15 |

| Overall dimension (mm) | 1500×3450×3780 | 1900×3450×4160 | 4260×3647×5366 |

| Material of table | Manganese | Manganese | Manganese |

| Ventilation requirements (m3/h) | 4000 | 6000 | 8000 |

| Material of Protective lining | Manganese/Cast alloy | Manganese/Cast alloy | Manganese/Cast alloy |

| Material of blast chamber | Mild steel | Mild steel | Mild steel |

★The technical data is not binding and may be subject to change.

★Depending on the type of parts, production method, etc.,further machine types and measurement specification sheets upon request.

Swing Tables Shot Blasting Machines Basic Specification

| ITEM | RTD1000 | RTD1200 | RTD2000 |

| Maximum Diameter of Rotary table (mm) | Φ1000 | Φ1200 | Φ1500 |

| Maximum workpiece weight (kg) | 400 | 400 | 1000 |

| Number of blast wheels and power (kw) | 11 | 2×7.5 | 3×11 |

| Material of table | Manganese | Manganese | Manganese |

| Ventilation requirements (m3/h) | 4000 | 6000 | 8000 |

| Material of Protective lining | Manganese/Cast alloy | Manganese/Cast alloy | Manganese/Cast alloy |

| Material of blast chamber | Mild steel | Mild steel | Mild steel |

★The technical data is not binding and may be subject to change.

★Depending on the type of parts, production method, etc.,further machine types and measurement specification sheets upon request.

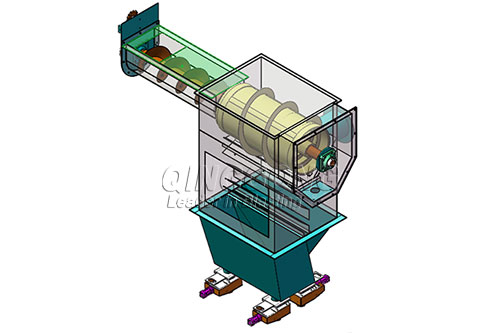

Qinggong Machinery patented wing rotary tables shot blasting machine solution greatly increase the production efficiency comparing with the single rotary table shot blasting machine. The advantages of this completely new patented design as follows:

1.This kind of shot blasting unit has twin rotary tables, one table can can be offloaded and loaded workpieces during the other rotary table inside the blasting chamber doing blasting job.

2.The rotary table designed on the door of the blasting chamber, The workpieces can be directly loaded on the table and offloaded from the table without any obstacles above it so as to greatly convenient loading and offloading.

3.Each rotary table use one gearmotor to drive the rotary system, and the rotary speed can be variable by frequency inverter inside the electric control box.

4.The whole shot blasting process is airless, and dust collecting system use high efficient cartridge type of filtering system, which is a very high compact design in case the end user have space restriction problems.

Blast cabinet

★Welded by steel plates and profile steel, have enough strength and rigidity.★ZGMn13 steel guard plate, which is hard enough to deal with the shot blasting from 35HRC to more than 55HRC.

★High impact toughness can make full use of the reflection kinetic energy of shot to continue to blast cleaning the surface of work piece, so greatly enhance the cleaning efficiency and quality.

★High chrome wear resistant cast iron grate guard plate which protect the screw conveyor and prevent big clump to get into the hopper damaging the bottom screw conveyor

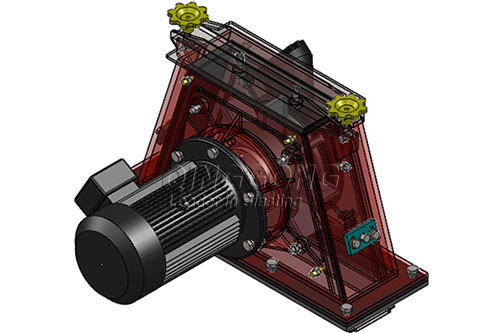

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.★impeller adopted #40 Chrome wear resistant cast iron.

★High chrome wear resistant cast iron for blades, control cage, abrasive distributor.

★Dynamic and static balance.

★Blades of impeller weight tolerance≤±1.5g.

★Unbalanced torque tolerance≤±7.5Nmm.

★Direct drive blast wheel with special motor bearings means less spare parts, less noise, energy-efficient, large abrasive flow rate and good cleaning effect ,etc. advantages.

★Machined housing ensures proper alignment of all internal parts.

★Less part wear due to greater concentricity and more precise alignment.

★Safety interlock is fitted on the housing cover to protect the workers safety.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax★Abrasive flow is indicated at the ammeter at the electrical switch and control box.

★Adjusting the bolt on the abrasive control valve can conveniently adjust the abrasive flow rate to an required amount

★In order to be able to dismount the abrasive control unit from the silo for repair works and to avoid any abrasive outflow for each unit one manual slide is installed in front of the abrasive control unit.

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of hte good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recyling rates of the abrasive and high quality surface finishing is achieved.

- +86-13235322903