-

-

Qingdao Qinggong Machinery experienced know-how engineer team are developed a shot blasting machine which can integrated in the concrete block/interlock block layers production line, The shotblasting machine for concrete/interlock block layers that can handle maximum product width of 1000mm and 1200mm.

Video

Qingdao Qinggong Machinery experienced know-how engineer team are developed a shot blasting machine which can integrated in the concrete block/interlock block layers production line, The shotblasting machine for concrete/interlock block layers that can handle maximum product width of 1000mm and 1200mm.

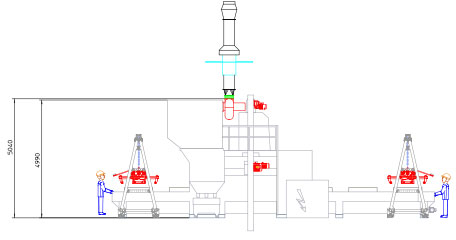

ShotBlaster Line with Stop and Go Mode

Which is mainly developed for All the block and interlock manufacturers, this kind of shot blaster lines have a very good finished goods in the market compared to companies owned German lines. It usually include: feeding-in-feeding out conveyor, 2 cubers for loading and stacking the products with telescopic guidance and pneumatic clamps , or slewing crane for carrying the layers,

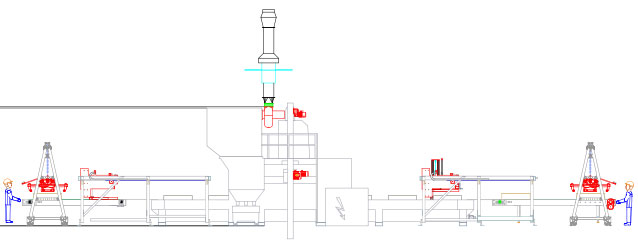

ShotBlaster Line with Continuous Mode

Transport belt for block layers :in special execution, equipped with support stripes arranged across the passage direction in order to prevent the ball-race effect and thus a shift of the stones within the block layer so that the unloading gripper can clamp the stone layer without any problem. Transport belt driving station:continuously variable for a passage speed from 2.5 up to 11 m/min, installed on the belt reversing roller in the outlet area.

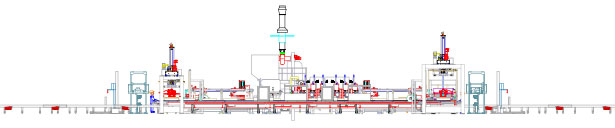

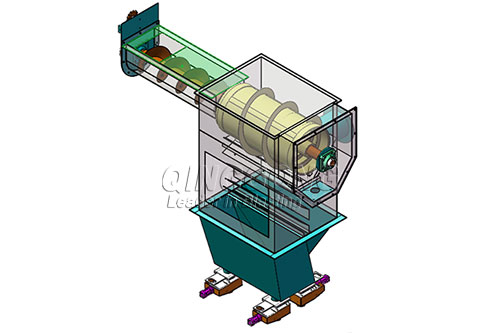

ShotBlaster Integrated with the Stone Layers Production Line

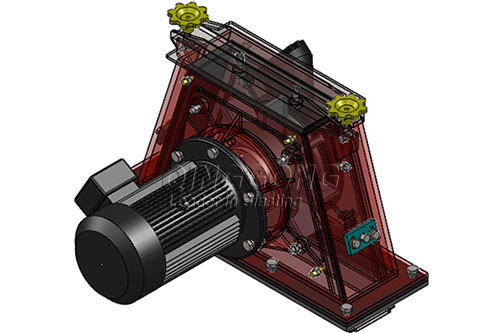

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.

- +86-13235322903