-

-

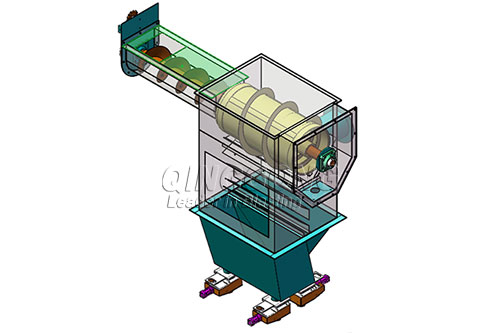

Shot Blasting Machine with continuous roller conveyor, rubber belt/metal mesh belt conveyor is mainly used for surface roughening treatment of marbles, granites, concrete products and nature stone. It has a strong market competition and prospective application in stone industry.

Videos

QGS Series Roller Conveyor Type for Pavers Length ≥60cm

Technical Specifications

| Machine Model | QGS600 | QGS800 | QGS1000 | QGS1200 | QGS1500 |

| Max. working width of machine(mm) | 600 | 800 | 1000 | 1200 | 1500 |

| Max. working height of machine(mm) | 400 | 400 | 400 | 400 | 400 |

| Working speed(frequency adjustable) m/min | 0.5~6 | 0.5~6 | 0.5~6 | 0.5~6 | 0.5~6 |

| number of wheels×power(kw) | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 |

| Vertical wheel optional | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 |

| Foundation pit required | No | No | No | No | No |

★The technical data is not binding and may be subject to change.

★Depending on the type of parts, production method, etc.,further machine types and measurement specification sheets upon request

QGP Series Rubber belt Type for Pavers Length ≤60cm

QGP Series Rubber belt Type for Pavers Length ≤60cm

Technical Specifications

| Machine Model | QGP600 | QGP800 | QGP1000 | QGP1200 | QGP1500 |

| Max. working width of machine(mm) | 600 | 800 | 1000 | 1200 | 1500 |

| Max. working height of machine(mm) | 400 | 400 | 400 | 400 | 400 |

| Working speed(frequency adjustable) m/min | 0.5~6 | 0.5~6 | 0.5~6 | 0.5~6 | 0.5~6 |

| number of wheels×power(kw) | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 |

| Vertical wheel optional | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 |

| Foundation pit required | No | No | No | No | No |

★Depending on the type of parts, production method, etc.,further machine types and measurement specification sheets upon request

Stone/Concrete Block Shot Blasting Machine are predominantly used to blast marbles, granites, concrete blocks to create an improved aesthetic appearance, taking out cement and making styling attributes such as granite chips visible. The working principle: different sized abrasive, thrown by the rapidly rotating blast wheel, is accelerated towards the surface being prepared. Huge impact force of the abrasive quickly etches a unique three-dimensional character of the surface. The products processed in this way have a high quality surface appearance without overlapped and dead zone, it also have high productivity efficiency and low cost. Comparison with the old power blader and singeing process method, it have higher efficiency and lower cost, and if connected to our dust collector, the dust and contaminants will be recycled automatically at a very low dust emission level, which comply with EU environmental standards.The concrete block/stone blast machine can be integrated into a production line due to its modern control system with the relevant interfaces, different belt lengths and well coordinated transfer stations (e.g. sheets or rollers). The machines can be operated easily using a Siemens Touchpanel.

Speed adjustment of conveyor and blast wheels is controlled through an Inverter.

The number and the position of the blast wheels can change depending on the geometry and on the work pieces (in some cases it is requested only the blasting of the upper side, in some other cases also of the lateral side). Loading and unloading of the work pieces on the conveyor can be done manually or through automatic clamps.

With proper regulated control and type of shot used in the shot blast machine, it is possible to produce different surface finishes to produce “antique” effect on marble stones and “bush-hamering” effect on cement products.

Qingdao Qinggong Machinery Stone/Concrete Block Shot Blasting Machine can be sized to treat workpiece widths from 600 to 2000 mm. Both indexing and continuous operations are possible. The belt conveyor/roller conveyor runs smoothly, at speeds from 2.5m/min to 14m/min.

The advantages

• This is assured by smooth/stepless speed control, electro-pneumatic dosage regulation and optimal blast wheel positioning.

• Furthermore, the use of hardened tool steel for the blast wheel wear parts assures a long service life.

Whilst lowering your cost per part, high values can be added to your concrete/stone products due to the consistent, uniform quality finish achieved at high process speed.

The optional use of two, three or four blast wheels in special positioning and with programmed start/stop functionality, allows the targeted treatment of both the horizontal and vertical visible surfaces – e.g. on fence blocks, marble stone,kerbstones or block steps. Turbine type stone texturing machine, stone texturing machine, Rock shot blasting machine

Blow-off station

Stainless steel shot is the preferred abrasive for concrete/stone applications. After blasting, a blow-off station with a high pressure blower removes the shot from the surface of the concrete blocks/stone. The nozzles are adjustable in height and therefore adaptable for the treatment of different concrete block/stone sizes.

Blast cabinet

★Welded by steel plates and profile steel, have enough strength and rigidity.★ZGMn13 steel guard plate, which is hard enough to deal with the shot blasting from 35HRC to more than 55HRC.

★High impact toughness can make full use of the reflection kinetic energy of shot to continue to blast cleaning the surface of work piece, so greatly enhance the cleaning efficiency and quality.

★High chrome wear resistant cast iron grate guard plate which protect the screw conveyor and prevent big clump to get into the hopper damaging the bottom screw conveyor

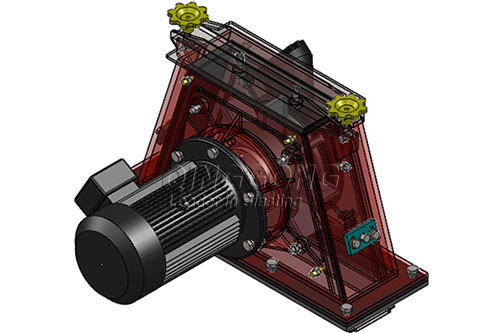

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.★impeller adopted #40 Chrome wear resistant cast iron.

★High chrome wear resistant cast iron for blades, control cage, abrasive distributor.

★Dynamic and static balance.

★Blades of impeller weight tolerance≤±1.5g.

★Unbalanced torque tolerance≤±7.5Nmm.

★Direct drive blast wheel with special motor bearings means less spare parts, less noise, energy-efficient, large abrasive flow rate and good cleaning effect ,etc. advantages.

★Machined housing ensures proper alignment of all internal parts.

★Less part wear due to greater concentricity and more precise alignment.

★Safety interlock is fitted on the housing cover to protect the workers safety.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax★Abrasive flow is indicated at the ammeter at the electrical switch and control box.

★Adjusting the bolt on the abrasive control valve can conveniently adjust the abrasive flow rate to an required amount

★In order to be able to dismount the abrasive control unit from the silo for repair works and to avoid any abrasive outflow for each unit one manual slide is installed in front of the abrasive control unit.

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of hte good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recyling rates of the abrasive and high quality surface finishing is achieved.

- +86-13235322903