-

-

Qinggong Machinery' custom design Blast Rooms are suit our customer'needs. For over forty years, Qinggong has been designing and manufacturing Blast Rooms from mild steel panels. Our panle design has proven to be strong, cost effective and easy to install.

In recent years, Qinggong has reacted to the market's request for Blast Rooms fabricated from other material. Concrete tilt-up panels, sandwich panels and welded plates have been used to meet our customer's requirements.

For aded longevity, Qinggong have included wall linings to protect the structure from blast media, including pvc, polyurea and rubber.

Industries that require this process include:

•Steel Fabricators•Construction Equipment

•Railcars

•Steel Tanks

•Trailers

•Oil Field Equipment

•Ship Building

QINGGONG offers a variety of reclaim floor designs and room configurations which allow us to design a blast room facility uniquely tailored to meet the economic production, safety and environmental concerns of each customer.

Environmental safe

Air-blasting eliminates many of the environmental problems and costs associated with chemical stripping because you don't have to manage or dispose of hazardous liquids.An QINGGONG blast room provides even greater potential for improving safety and reducing operating costs when you're cleaning, finishing or surface-profiling large work pieces. With the process contained in a specially designed enclosure, blast media and debris are isolated from the external environment. And the operator, equipped with QINGGONG safety gear, is fully protected.

Recovery floors: from simple to sophisticated

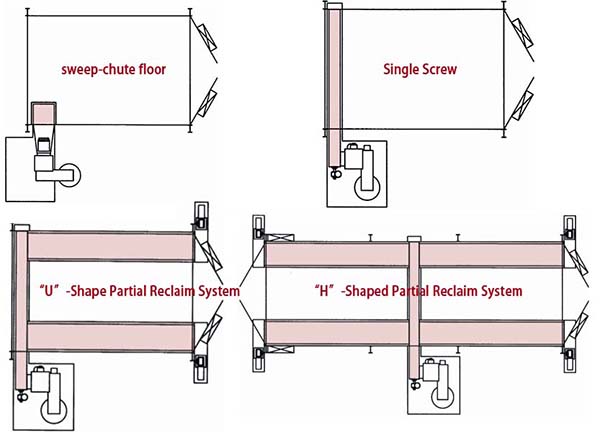

Qinggong offers recovery floors to meet almost any budget and production requirements. The sweep-chute floor shown below, for instance, delivers the economic and environmental benefits of media recycling at a modest cost.In higher volume applications where both production speed and labor cost become important considerations, you can select the Sweeper Blade Full Floor Reclaim System.

1.sweep-chute floor

The sweep-chute floor, delivers the economic and environmental benefits of media recycling at a modest cost.

1.sweep-chute floor

The sweep-chute floor, delivers the economic and environmental benefits of media recycling at a modest cost.2.Single Screw or Scraper Partial Reclaim System

The most economical floor design available. The system contains screw conveyor or craper conveyor, heavy duty screw belt and bucket elevator,air-wash separator, perforated plate rotary drum separator and oversized abrasive storage hopper with a caged man ladder and handrail. This can be expanded to an “H”,”U”, or full floor reclaim system and is best suited for low to medium production levels.

3.“H”-Shaped Partial Reclaim System

Adds two longitudinal conveyors along each side wall of the blast room allowing the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the work piece, to strike the side walls and fall into the conveyors, automatically reclaiming approximately 60-90 percent of the blast media. The reclaiming abrasive on the floor is pushed into the screw or scraper conveyors assemblies at the end of the work shift. The “H” shape floor design is typically used in a “flow-through” room configuration where heavy work pieces and/or material handling devices can drive into the room. This is best suited for medium to high production.

4.“U”-Shape Partial Reclaim System

Adds two longitudinal screw or scraper conveyors assemblies along each wall of the blast room and positions the cross screw or scraper conveyors along the back wall of the blast room. This allows the abrasive delivered from blasting nozzle, which is either blown or rebounded off the work piece, to strike the side walls and back wall of the blast room and fall into the reclaim system, A ”U”-shape floor design will automatically reclaim 60-90 percent of the blast media. The remaining abrasive on the floor is pushed into the metered shed plate screw assemblies at the end of the work shift, The “U”-shaped floor design is typically used in an “in-out” room configuration where heavy work pieces and/or material handling devices can drive into the room. This is best suited for medium to high production

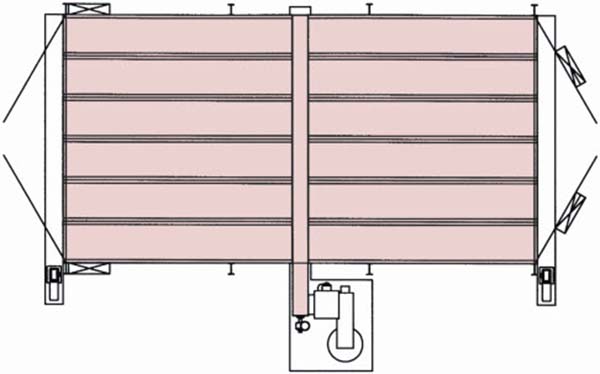

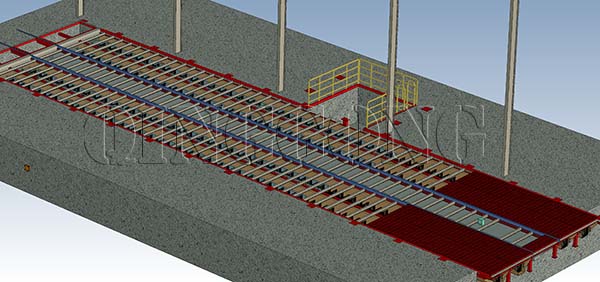

5.Unique Sweeper Blade Full Floor Reclaim System

A major benefit of this type of system is that it only requires a shallow concrete foundation. This can create substantial savings for the customer in comparison to other types of recovery systems. It also avoids the issue created by digging foundations in area that have high water table levels. The full floor reclaim design requires that the material handling of the work piece be intricately designed into the configuration of the room. Material handling of the work piece includes a work car/track system, an overhead monorail crane, an overhead bridge crane or guide rail work cars, heavy-duty floor grating and support steel sized to allow a forklift to drive onto the reclaim floor. This design can be used with any room configuration and is best.

A major benefit of this type of system is that it only requires a shallow concrete foundation. This can create substantial savings for the customer in comparison to other types of recovery systems. It also avoids the issue created by digging foundations in area that have high water table levels. The full floor reclaim design requires that the material handling of the work piece be intricately designed into the configuration of the room. Material handling of the work piece includes a work car/track system, an overhead monorail crane, an overhead bridge crane or guide rail work cars, heavy-duty floor grating and support steel sized to allow a forklift to drive onto the reclaim floor. This design can be used with any room configuration and is best.Advantages A major benefit of this type of system is that it only requires a shallow concrete foundation. This can create substantial savings for the customer in comparison to other types of recovery systems. It also avoids the issue created by digging foundations in area that have high water table levels.

- +86-13235322903