-

-

Mechanical pre-descaling and final chemical surface treatment of hot-rolled stainless steel strip (Cr-Ni, titanium strip) and Si-alloy strip are almost exclusively carried out in integrated processing lines that combine annealing, cooling and mechanical descaling.QINGGONG strip blast cleaning systems are renowned in this field and offer clear benefits.

Speed:25-60m/min

Strip width:500mm-1600mm

Turbines:55-160kw

Threat:

High carbine steel

Inox steel

MKM steel

Applications

• High performance mechanical descaling of steel strip (stainless and silicon steel, low carbon, titanium) integrated in highly sophisticated continuous production lines• Type series ranging up to strip widths of 500 mm to 1600mm

• Modular concept meeting production requirements

Benefits

• Reliable and economical operation resulting in a high degree of surface cleanliness• Blast cleaning and surface qualities up to Sa 2 - Sa 2.5

• High overall efficiency and reliability, low space requirements

• Easy adaptation to strip width

• Blast wheel arrangement and concept ensures maximum exploitation of blasting energy and intensity and prevents from blasting interferences

• Efficient abrasive blow-off, maximum abrasive cleaning and recovery, efficient dust collection

• High wear-resistant execution of parts subject to wear

• Continuous further development ensures application of latest technology; high sustainability Descaling of narrow-, medium-, and wide steel strip.

During the different processing phases,QINGGONG blast cleaning systems can be adjusted to fit specification. The adjustment will be made by regulating the abrasive throughput rate, by varying the abrasive throwing speed or the breadth of abrasive impingement. This guarantees maximum power utilisation, and the most efficient use of resources.

The equipment is equally suitable for continuous as well as for push-pull pickling lines.

Specific surface finish requirements can be met by operating several machine modules in sequence. Cold-rolled steel strip can pass through the system without blast cleaning.

Blast cabinet

★Welded by steel plates and profile steel, have enough strength and rigidity.★ZGMn13 steel guard plate, which is hard enough to deal with the shot blasting from 35HRC to more than 55HRC.

★High impact toughness can make full use of the reflection kinetic energy of shot to continue to blast cleaning the surface of work piece, so greatly enhance the cleaning efficiency and quality.

★High chrome wear resistant cast iron grate guard plate which protect the screw conveyor and prevent big clump to get into the hopper damaging the bottom screw conveyor

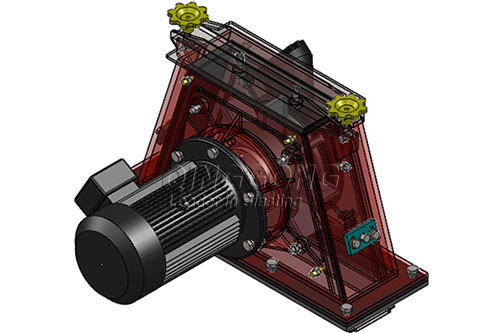

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.★impeller adopted #40 Chrome wear resistant cast iron.

★High chrome wear resistant cast iron for blades, control cage, abrasive distributor.

★Dynamic and static balance.

★Blades of impeller weight tolerance≤±1.5g.

★Unbalanced torque tolerance≤±7.5Nmm.

★Direct drive blast wheel with special motor bearings means less spare parts, less noise, energy-efficient, large abrasive flow rate and good cleaning effect ,etc. advantages.

★Machined housing ensures proper alignment of all internal parts.

★Less part wear due to greater concentricity and more precise alignment.

★Safety interlock is fitted on the housing cover to protect the workers safety.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax★Abrasive flow is indicated at the ammeter at the electrical switch and control box.

★Adjusting the bolt on the abrasive control valve can conveniently adjust the abrasive flow rate to an required amount

★In order to be able to dismount the abrasive control unit from the silo for repair works and to avoid any abrasive outflow for each unit one manual slide is installed in front of the abrasive control unit.

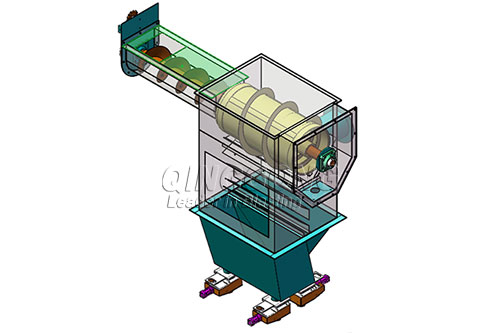

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of hte good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recyling rates of the abrasive and high quality surface finishing is achieved.

Products pictures

- +86-13235322903