-

- Continuous Rocker Barrel shot blasting machine is automatic, continuous, dust-free shot blasting equipment, with a high degree of flexibility to meet the changing production requirements. It can quickly adapt to the production efficiency, processing technology and market demand changes. It can be easily integrated into the production line with other processing equipment, which can realize the automatic production process. This can ensure the whole production process line reach to the high production efficient and low-cost operation while improving the working environment.

Video

Basic Specification

| Type | DT-11-350 | DT-14-450 | DT-17-650 | DT 20-650 |

| DT-14-650 | ||||

| DT-14-850 | DT-17-850 | DT 20-850 | ||

| DT-14-1050 | ||||

| Max. workpiece diagonal (mm) | 400 | 850 | 980 | 1150 |

| Throughput rate (t/h) | 2-5 | 8-25 | 15-33 | 15-38 |

| Max. workpiece weight (kg) | 30 | 150 | 150 | 150 |

| Number of blast wheels | 3 | 4-10 | 6-10 | 6-10 |

| Power per blast wheel (kW) | 45 | 37-45 | 37-45 | 37-45 |

The shot blasting are sectional and contain individual modules for easily transportation and installation.

The inlet and outlet vestibule modules are separated from the shot blasting chamber through a multi-rubber curtains to block the spattered blasting media.

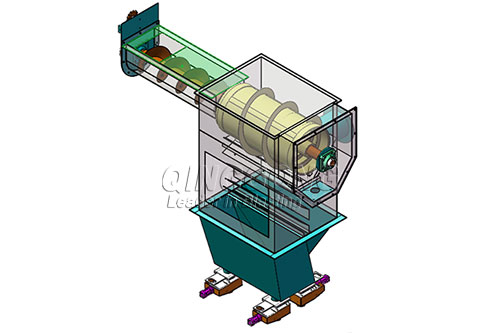

The shot-blasting machine is tilted slightly downward in the flow direction of the workpiece, including the rocker barrel, abrasive reclaim system, blasting turbine system, dust collector system and electric control panel system.

The polygon shaped trough is made by high manganese steel plate with a thickness 16mm or 20mm, the perforated swing-trough is advantageous to reclaim the abrasive.

The polygon shaped trough swing angle is in the 120° stroke to gently tumble the workpieces.The frequency of the rocking motion of the trough and the abrasive supply to the blast wheels are controlled based on pre-programmed parameters depending on the flow rate and volume of parts.

This ensures optimum blast cleaning results and minimum wear, even when the flow-rate of parts is irregular. The high power abrasive streams - aimed at parts from above - reach, and thoroughly clean all surfaces and interior areas.

Application

Removing sand and cores from castingsDescaling castings and forgings

Handling mixed and single products runs

Cleaning cluster

Keeping the blast cleaning performance at a consistently high level, regardless of any fluctuations in production rates

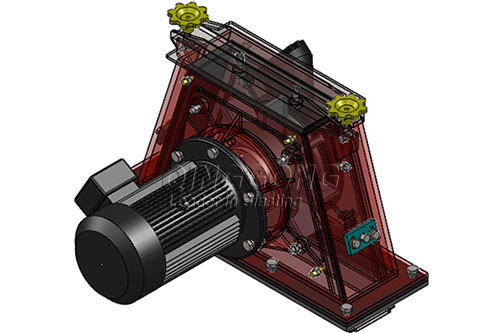

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.

- +86-13235322903