-

- Qinggong Machinery offers a range of roller conveyors from small simple machines to construction blasters, heavy duty machines and complete preservation lines. Qinggong Machinery’s extensive experience in this field caters for all component sizes as well as customer specific solutions. Working speeds from 0.5 m/min for a small roller conveyor machine to 20m/min for a heavy skew roll machine are achievable.

Video

Roller Conveyor Shot Blasting Machine Type QGB Series

| Type | unit | QGB600 | QGB1000G | QGB1500 | QGB2000 | QGB2500 | QGB3000 |

| Effective blasting width | mm | 600 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Dimension of entrance(W×H) | mm | 800×550 | 1200×550 | 1700×550 | 2200×550 | 2700×550 | 3200×550 |

| Work speed to achieve a cleaning of Sa2.5 ISO8501 | m/min | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 |

| Number of wheels×power | kW | 4×7.5/11 | 4×11/15 | 4×11/15 | 6×11/15 | 8×11/15 | 8×11/15 |

| Wheel optional | kW | — | — | — | 4×15 | 6×15/18.5 | 6×15/18.5 |

| Abrasive initial filling capacity | kg | 2000 | 4000 | 4000 | 4500 | 6000 | 6000 |

| Processed length of work piece | mm | 1200~12000 | 1200~6000 | 1200~12000 | 3000~12000 | 2400~12000 | 3000~18000 |

| Foundation pit required | No | No | No | Yes | Yes | Yes |

★The technical data is not binding and may be subject to change.

★Depending on the type of parts, production method, etc.,further machine types and measurement specification sheets upon request

Roller Conveyor Shot Blasting Machine Type QGX Series

| Type | unit | QGX600 | QGX1200 | QGX1200 | QGX1500 | QGX1800 | QGX2000 |

| Effective blasting width | mm | 600 | 1200 | 1200 | 1500 | 1800 | 2000 |

| Dimension of entrance(W×H) | mm | 800×1400 | 1400×1600 | 1400×2000 | 1700×1600 | 2000×1700 | 2200×2400 |

| Work speed to achieve a cleaning of Sa2.5 ISO8501 | m/min | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~2 |

| Number of wheels×power | kW | 8×7.5/11 | 8×11/15 | 8×11/15 | 8×11/15/18.5 | 8×11/15 | 12×11/15/18.5 |

| Wheel optional | kW | — | — | 10×11/15 | 10×11/15/18.5 | 10×11/15/18.5 | 14×11/15/18.5 |

| Abrasive initial filling capacity | kg | 4000 | 4000 | 4000 | 4500 | 8000 | 11000 |

| Processed length of work piece | mm | 1200~12000 | 1200~6000 | 1200~12000 | 3000~12000 | 2400~12000 | 2400~18000 |

| Foundation pit required |

|

Yes | Yes/No | Yes/No | Yes | Yes | Yes |

★The technical data is not binding and may be subject to change.

★Depending on the type of parts, production method, etc.,further machine types and measurement specification sheets upon request.

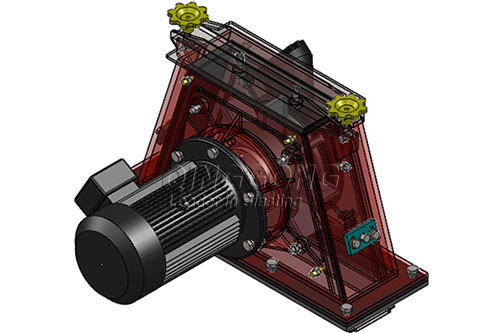

Blast turbines

★Cantilever centrifugal high efficiency blast wheel, can operate clockwise or counter-clockwise, optimum abrasive flow rate for faster cleaning.

★Particular guard liner structure increase the abrasion resistant lifespan 60% to 200%.

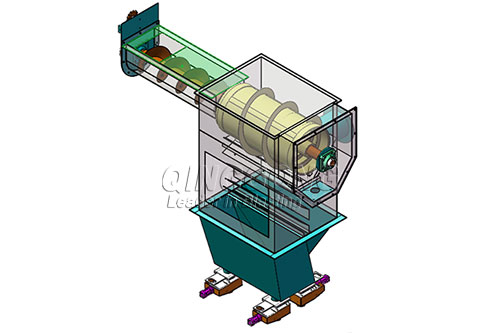

Pneumatic Abrasive dosing units

★Patented pneumatic control abrasive gate valve, which depend on cylinder to control stroke so as to control the blast wheel in long-distance. This avoids motor burned, blast wheel jammed, shot idling blast and people injured caused by common abrasive control valve closure lax

Abrasive cleaner

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and munimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdwon rate.

- +86-13235322903